Valves and guides are essential components in machinery, controlling the flow of fluids, gases, or solids. They ensure efficient operation, safety, and durability in various systems. Proper alignment and functionality are critical for optimal performance, making them indispensable in engines and industrial applications.

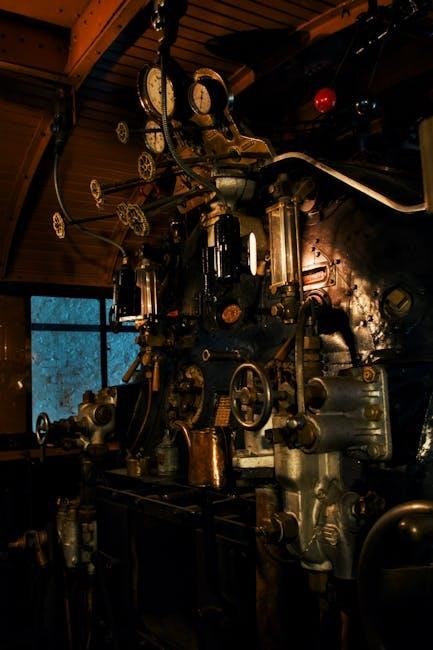

Overview of Valves and Guides in Machinery

Valves and guides play a crucial role in controlling the flow of fluids, gases, or solids in machinery. They ensure efficient operation by regulating pressure, direction, and flow rate. Guides, such as valve stem guides, maintain proper alignment, preventing wear and tear. Together, they contribute to the overall performance, safety, and longevity of mechanical systems. Their design and functionality are tailored to specific applications, making them indispensable in industries ranging from automotive to industrial machinery. Proper maintenance is essential to sustain their efficiency and reliability over time.

Importance of Valves and Guides in Engine Operation

Valves and guides are vital for efficient engine operation, ensuring proper airflow and fluid control. They regulate intake and exhaust processes, enabling optimal combustion and power generation. Guides maintain valve alignment, reducing wear and tear, while valves prevent leaks and maintain pressure. Their precise operation enhances fuel efficiency, reduces emissions, and prolongs engine lifespan. Regular maintenance of these components is crucial for sustaining performance and reliability, making them indispensable in modern automotive and industrial applications.

Types of Valves

Valves are categorized into inlet, exhaust, solenoid, ball, gate, butterfly, and check valves, each designed for specific functions in fluid and gas control systems.

Inlet and Exhaust Valves

Inlet and exhaust valves are critical components in internal combustion engines, regulating the flow of air-fuel mixture and exhaust gases. Inlet valves open to allow the intake of air and fuel, while exhaust valves expel combustion gases. These valves operate in sync with the engine’s pistons, ensuring efficient combustion and power generation. Proper alignment and sealing are maintained by valve guides, which prevent wear and ensure precise operation over time.

Valve guides play a crucial role in maintaining engine performance by keeping the valves aligned and reducing wear. Regular maintenance is essential to prevent damage and ensure optimal engine function.

Special Purpose Valves

Special purpose valves are designed for unique applications, offering tailored solutions beyond standard valve functions. These valves include pressure relief, check, and solenoid types, each addressing specific operational needs. They often feature advanced materials and coatings to withstand harsh conditions, such as high pressure or corrosive environments. Guides in these systems are engineered to maintain precise alignment, ensuring reliable operation and minimizing wear. Their versatility makes them indispensable in specialized machinery and industrial processes, providing critical control over fluid and gas flow.

Types of Guides

Guides are crucial components that ensure proper valve alignment and smooth operation. They include valve stem guides, which support the valve stem, and valve seat guides, which align the valve seat.

Valve Stem Guides

Valve stem guides play a critical role in engine operation by ensuring the proper alignment and movement of valve stems. They are typically made from durable materials such as metal alloys or ceramic-coated components to withstand high temperatures and wear. Over time, these guides can experience wear and tear, leading to issues like increased oil consumption or reduced engine performance. Regular inspection and maintenance are essential to prevent premature damage and ensure smooth engine functionality. Properly functioning valve stem guides are vital for efficient combustion and overall engine health.

Valve Seat Guides

Valve seat guides are crucial components that support and align valve seats in engines, ensuring proper sealing when valves close. This prevents leaks and maintains combustion efficiency. Made from durable materials like metal alloys or ceramic-coated components, they withstand high temperatures and wear. Regular inspection and maintenance are essential to prevent premature damage, which can lead to decreased engine performance and fuel efficiency. Properly functioning valve seat guides are vital for optimal engine operation and longevity, ensuring reliable engine function over time.

Materials Used for Valves and Guides

Valves and guides are crafted from durable materials like metal alloys, stainless steel, and ceramic-coated components. These materials ensure resistance to corrosion, high temperatures, and wear, providing longevity and reliability in various applications. The choice of material depends on the operating conditions, with coated components offering enhanced performance in extreme environments. Proper material selection is crucial for maintaining optimal functionality and minimizing maintenance needs over time;

Metal Alloys in Valve Construction

Metal alloys are widely used in valve construction due to their durability, strength, and resistance to corrosion and high temperatures. Common alloys include stainless steel, titanium, and nickel-based materials, each offering unique properties. Stainless steel is corrosion-resistant, while titanium provides lightweight strength. Nickel alloys excel in extreme temperature conditions, making them ideal for harsh environments. These materials are carefully selected to ensure valves operate reliably in diverse applications, from automotive to industrial systems, providing long-term performance and minimizing maintenance needs.

Ceramic and Coated Components

Ceramic and coated components are increasingly used in valves and guides for enhanced durability and corrosion resistance. Ceramic materials offer exceptional hardness and wear resistance, making them ideal for high-stress applications. Coatings, such as titanium nitride or chrome, provide additional protection against friction and corrosion. These components are particularly beneficial in harsh environments, extending the lifespan of valves and guides. Their use minimizes maintenance and ensures consistent performance across various industries, including automotive and industrial machinery.

Functionality and Operation

Valves regulate the flow of fluids, gases, or solids by opening or closing passageways, while guides ensure precise alignment and smooth movement of valve components, optimizing performance and reducing wear.

Role of Valves in Fluid Control

Valves play a critical role in fluid control by regulating the flow of liquids, gases, or solids within a system. They enable the precise direction, throttling, or complete shutdown of flow, ensuring operational efficiency. Whether manual, automated, or hydraulic, valves are essential for maintaining pressure, temperature, and fluid dynamics. Their design varies, from inlet and exhaust valves in engines to specialized valves for industrial applications. Proper valve operation prevents leakage, corrosion, and system failure, making them indispensable in machinery and fluid management systems across various industries.

How Guides Ensure Proper Valve Alignment

Valve guides play a crucial role in maintaining proper valve alignment, ensuring precise movement and preventing wear. They keep the valve stem correctly positioned, allowing it to move smoothly within the engine or system. Guides protect the valve seat from misalignment, which could cause improper sealing or damage. By maintaining accurate alignment, guides enhance engine performance, reduce wear on components, and ensure efficient operation. Their durability and precise engineering are essential for optimal valve function and longevity in various mechanical systems.

Maintenance and Repair

Regular inspection of valves and guides is crucial for detecting wear and damage; Cleaning, lubricating, and replacing worn components ensure optimal performance and prevent system failure over time.

Inspecting Valve Guides for Wear

Inspecting valve guides involves checking for excessive wear, scoring, or damage. Guides with significant wear may cause improper valve seating, leading to reduced engine performance and increased emissions. Technicians often use visual inspections or specialized tools to measure guide clearance. Excessive clearance indicates wear, requiring replacement. Proper lubrication during inspection helps prevent damage. Regular maintenance ensures longevity and efficiency of engine operation, preventing costly repairs. Early detection of wear can extend the lifespan of both guides and valves.

Replacing Worn Valve Stems and Guides

Replacing worn valve stems and guides is crucial for maintaining engine efficiency. When guides are damaged, they can cause misalignment, leading to improper valve sealing. Technicians typically remove the valve assembly, inspect the guide clearance, and replace worn components with precision-fit parts. Proper installation ensures tight seals and smooth operation. Lubrication during reassembly prevents premature wear. Regular replacement prevents engine damage, reduces emissions, and enhances overall performance. It is a cost-effective measure to avoid major repairs and extend engine lifespan.

Applications of Valves and Guides

Valves and guides are integral in automotive engines, industrial machinery, and plumbing systems, ensuring precise fluid and gas control, and preventing leakage and system inefficiency.

Automotive Engines

In automotive engines, valves regulate the flow of air and fuel into cylinders and exhaust gases out. Guides ensure proper valve alignment, preventing wear and tear. They are critical for engine performance, fuel efficiency, and reducing emissions. Worn guides can lead to decreased efficiency and potential engine damage, emphasizing the need for regular maintenance and inspections. Proper functionality of these components is vital for smooth engine operation and longevity.

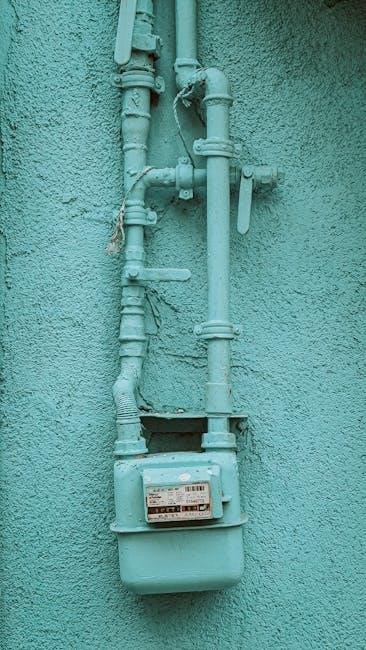

Industrial Machinery and Plumbing Systems

In industrial machinery, valves control fluid flow, while guides maintain alignment and longevity. Plumbing systems rely on valves to regulate water and gas flow, ensuring efficient distribution. Guides in these systems prevent wear, reducing leaks and maintenance needs. Proper installation and maintenance of both components are crucial for system reliability and safety, ensuring optimal performance across various industrial applications and municipal infrastructure. Their durability and functionality are key to uninterrupted operations in both machinery and plumbing networks.

Common Issues and Troubleshooting

Valves and guides often face issues like leakage, corrosion, and wear. Regular inspections and timely replacements are crucial to prevent system failures and ensure smooth operation.

Leakage and Corrosion in Valves

Leakage and corrosion are common issues in valves, often caused by worn-out seals, improper connections, or exposure to harsh chemicals. These problems can lead to fluid loss, reduced efficiency, and potential system damage. Regular inspections and maintenance are essential to identify early signs of wear or corrosion. Replacing damaged components and applying protective coatings can help mitigate these issues. Addressing leakage and corrosion promptly ensures reliable operation and extends the lifespan of valves in various applications, from engines to industrial systems.

Wear and Tear in Valve Guides

Valve guides are susceptible to wear and tear due to constant motion and high-temperature exposure. Over time, this can lead to loosened guides, reduced precision, and decreased engine performance. Regular lubrication and inspections help identify early signs of wear. Replacing worn guides and stems ensures proper valve alignment and prevents further damage. Addressing wear promptly is crucial for maintaining engine efficiency, reducing emissions, and avoiding costly repairs. Proper maintenance extends the lifespan of valve guides, ensuring smooth engine operation across various applications.

Role of Valve Guides in Engine Performance

Valve guides play a crucial role in engine performance by ensuring proper valve alignment, reducing wear, and maintaining optimal engine efficiency and longevity.

Impact on Fuel Efficiency

Properly functioning valve guides significantly improve fuel efficiency by ensuring precise valve alignment and optimal combustion chamber sealing. Misaligned valves due to worn guides can lead to inefficient fuel combustion, reducing overall engine performance. Efficient valve operation minimizes energy loss, directly contributing to better fuel economy. Regular maintenance of valve guides is crucial to sustain optimal engine efficiency and reduce fuel consumption over time.

Reducing Emissions

Valve guides play a crucial role in minimizing emissions by ensuring precise valve operation and efficient combustion. Properly aligned valves promote complete fuel combustion, reducing harmful emissions like carbon monoxide and hydrocarbons. Worn guides can lead to inefficient combustion, increasing emissions. Regular maintenance of valve guides helps maintain tight engine performance, reducing environmental impact. Efficient valve operation also supports adherence to stricter emissions standards, contributing to cleaner and more sustainable engine operation over time.

Selecting the Right Valves and Guides

Selecting the right valves and guides involves assessing durability, fitment, and application-specific needs. Proper choices ensure optimal performance, minimize wear, and extend system lifespan effectively.

Factors to Consider

When selecting valves and guides, consider material durability, application-specific needs, and system compatibility. Assess factors like pressure ratings, temperature thresholds, and flow requirements. Ensure proper fitment and alignment to prevent wear. Evaluate the environment—corrosive, high-temperature, or heavy-duty settings may require specialized materials. Additionally, consider maintenance accessibility and cost-effectiveness. Consulting manufacturer specifications and expert recommendations can guide optimal selections, ensuring long-term performance and reliability in various mechanical systems.

Case Studies of Successful Implementations

Successful implementations of valves and guides are evident in automotive and industrial applications. For instance, high-performance engines utilize advanced valve materials, reducing wear and improving fuel efficiency. In industrial settings, custom-designed guides have minimized downtime and enhanced operational efficiency. These case studies highlight how tailored solutions address specific challenges, ensuring optimal performance and longevity. Real-world applications demonstrate the critical role of valves and guides in achieving reliability and sustainability across diverse mechanical systems.

Future Trends in Valve and Guide Technology

Future trends in valve and guide technology include smart valves, advanced materials, and energy-efficient designs, enhancing performance and reducing environmental impact.

Advancements in Materials Science

Advancements in materials science have led to the development of high-performance materials for valves and guides, such as ceramic coatings and high-temperature alloys. These materials enhance durability, reduce wear, and improve thermal resistance. Innovations in 3D printing technology are also enabling the creation of complex geometries and customized components. Additionally, the use of smart materials that can adapt to environmental changes is being explored, offering potential for self-healing coatings and improved efficiency in extreme conditions.

Smart Valves and Guides

Smart valves and guides integrate advanced technologies like sensors, AI, and IoT for real-time monitoring and adaptive control. These systems optimize performance by adjusting to changing conditions, reducing wear and improving efficiency. Sensors embedded in smart valves enable predictive maintenance, detecting potential failures early. IoT connectivity allows remote operation and data analysis, enhancing safety and reliability. Self-diagnostic features and automated responses further reduce downtime, making smart valves and guides indispensable in modern, high-performance applications across industries.

Valves and guides are vital for efficient operation across industries, ensuring fluid control and proper alignment. Their evolution continues to enhance performance, safety, and durability in modern systems.

Valves and guides are critical components in machinery, ensuring precise fluid control and alignment. They are made from durable materials like metal alloys and ceramics. Regular maintenance, including inspections and replacements, prevents issues like leakage and wear. Proper selection and installation are vital for optimal performance. Their applications span engines, plumbing, and industrial systems. Addressing common issues promptly enhances efficiency and longevity, underscoring their importance in modern mechanical systems.

Final Thoughts on the Importance of Valves and Guides

Valves and guides are indispensable in ensuring efficient fluid control and alignment in machinery. Their proper functioning directly impacts fuel efficiency, emissions reduction, and overall system performance. Regular maintenance and timely replacements are crucial to prevent wear and leakage, enhancing durability. As critical components in engines and industrial systems, their importance cannot be overstated. Recognizing their value ensures reliable operation and optimal performance across various applications, making them fundamental to modern mechanical systems.